Worktop and Counter Repairs

Stone worktops (such as granite and marble or engineered stone such as quartz and corian) are repaired using specialist ultra-violet materials and other fillers. Our technicians are skilled in using fillers that blend into the remainder of the surface with the correct level of depth of colour.

Laminate Worktop Surfaces Repaired

Laminate surfaces are also mended. Fillers or hat waxes are used to create a smooth surface. The base colour of the worktop is matched. The detailed pattern is then re-created so that the repair and remainder of the surface blend seamlessly and undetectably. Finally, a hard-wearing lacquer is applied to protect the surface from further damage.

Wooden Worktop Repair

Wooden worktops are also repairable. Hard waxes or two pack fillers are applied to the damaged area and sanded to create and perfectly smooth surface. The base colour of the wood is then colour-matched and the grain effect applied to the surface using a fine artist paint brush. The repair is then sealed with a hard-wearing lacquer.

Worktop and Counter Repairs

For worktop repairs please call our experts on 020 8616 0350 for London and the South East and 01603 263842 for East Anglia. To see more information on our kitchen refurbishment service click here, and to see images of our latest surface repairs click here

Laminate worktop repair Case Study – As good as new

Discovering the damage

Imagine, it’s a week after your new kitchen has been fitted, every time you walk in the room it makes you smile from ear to ear, until on Saturday morning when you find a pan mark burnt into the worktop next to your hob. After an evening out with friends, your teenage son cooked beans on toast in the middle of the night and places the hot pan directly onto the new surface, leaving a clear impression of the pan base on your newly fitted worktop.

Who do you call? – The Refinishing Touch!

1: Removing the burnt areas

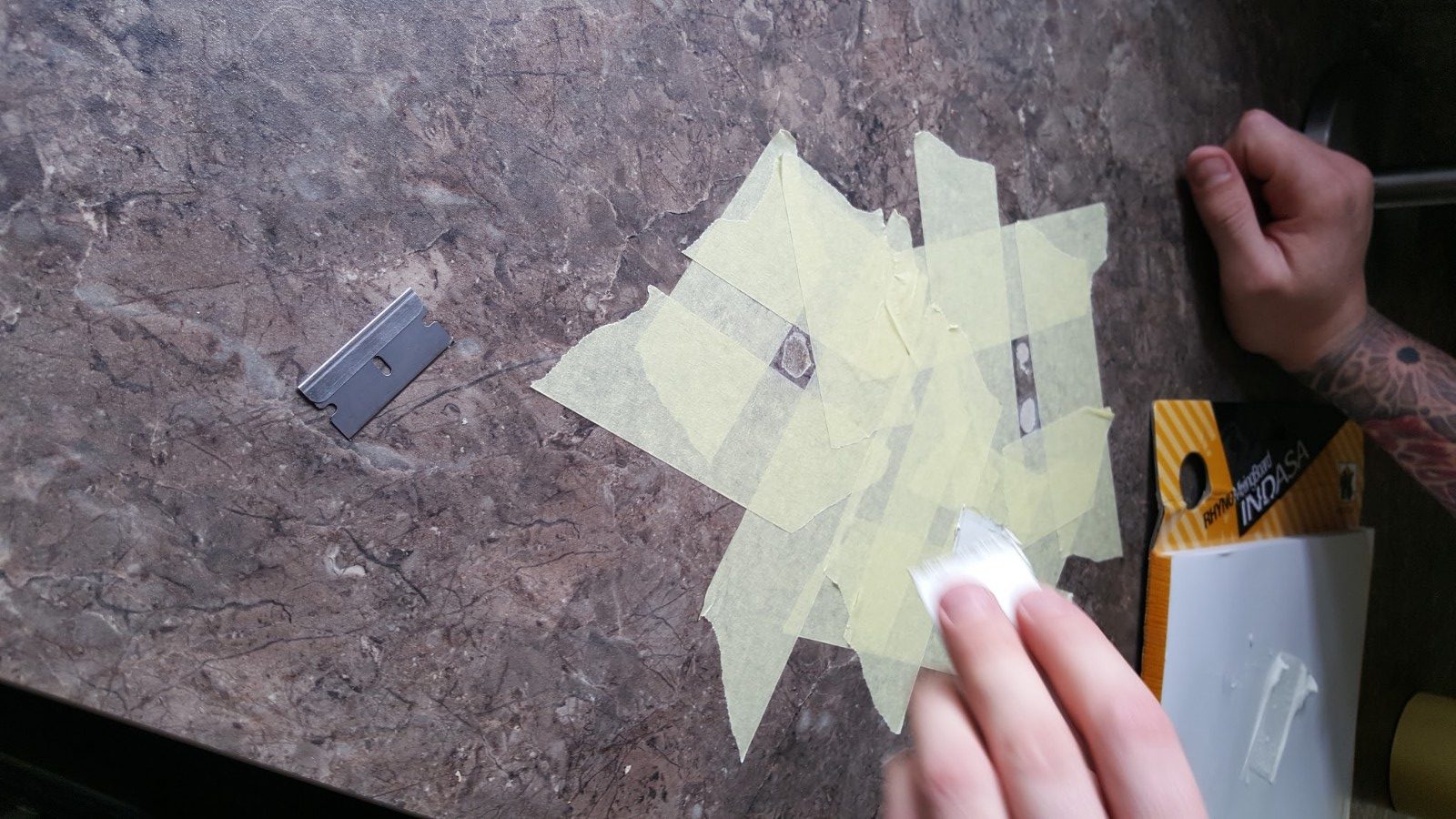

After our technician arrives on site and completes their visual survey of the damage, they assess the best way to repair the damaged area.

In this case our technician removes the burnt patches with a blade, taking great care to remove the minimal amount of the original surface as possible.

2: Prep the area

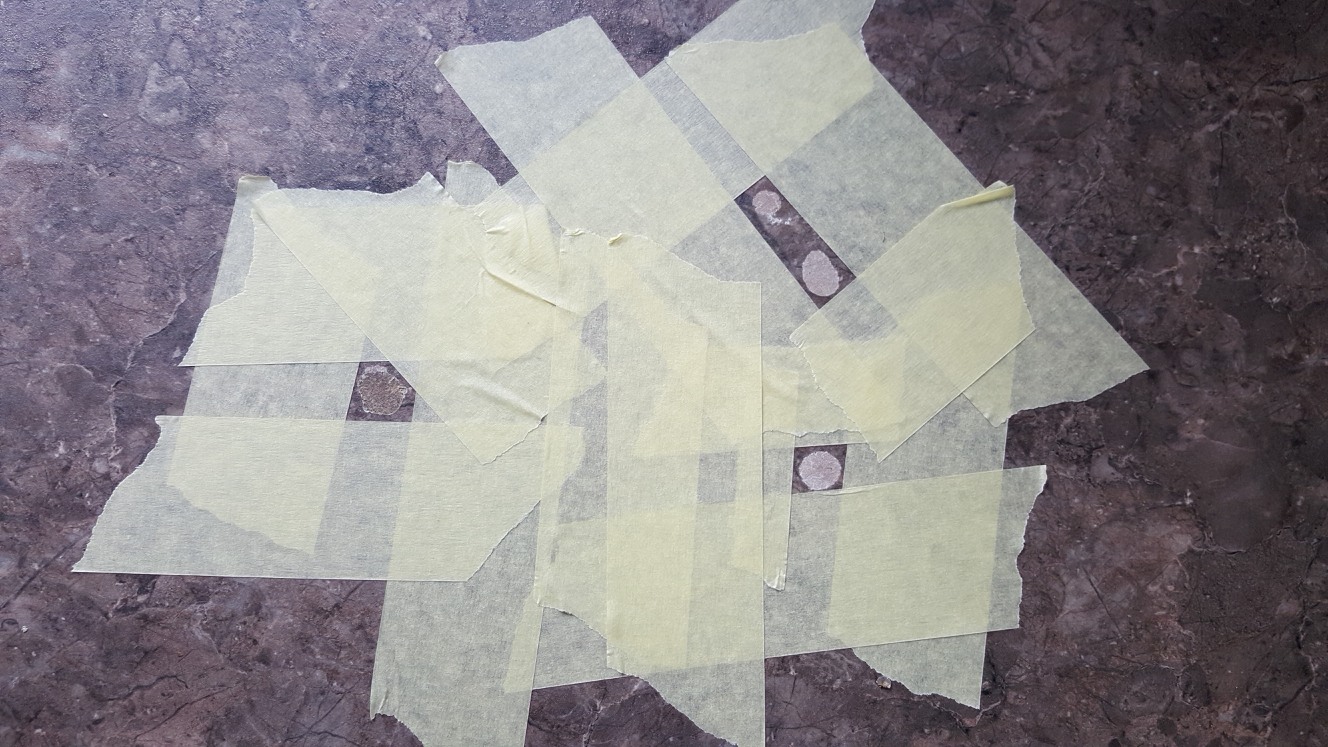

To keep the size of the repair area to a minimum our technician masks closely around the individual pieces of damage resulting from the pan burn, protecting the undamaged area around them.

3: Filling

After mixing a small quantity of specialist filler on a board, our technician then applies the filler into the damaged areas in the worktop. This has to be done in small, thin layers allowing time to dry between each layer and building up the filler until the damages are slightly over filled.

4: Thorough cleaning

After carefully sanding back the filler to the level of the surrounding worktop, Scott thoroughly cleans the area to remove any dust, grease or debris in preparation for the application of the colour.

5: Applying the colour

Our technician builds the colour required to make the damage disappear, slowly but surely applying layer upon layer, blending and texturising where necessary.

6: Finishing touches

One by one each area of damage becomes unnoticeable until the whole repair is finished with a hard wearing durable top coat.